Pneumatic Tyre

From the surface, tyres mightn’t appear all that complex and look more a composite of rubber, steel belts, and air. While it may be true years ago in a consumer market, tyre manufacturers in recent years are carrying production using entirely innovative and new concepts. It gives more durable, safer and high-performance products that are equally as valuable as any other automobile development.

Some of the most innovative tyre technologies, designs and engineering principles are discussed here that are likely to become industry standard soon enough; particularly with tyre in Dubai. This is because some of the best tyre companies are located there. The information would give you an edge on preparing your car wheels for the next innovation.

The Pneumatic Tyre Development:

Almost every consumer vehicle come equipped with this particular type of tyre in Dubai as well as in many different regions where the industry is on the rise. While early rubber tyres were sturdy, the introduction of Dunlop’s first pneumatic wheel way back in 1888 became the mainstay of almost every tyre model we see today. It’s donut-shaped body of chords and wires sheathed in rubber with compressed air filling.

Solid rubber tyres are indeed durable but they lack the driving comfort and element of smoothness. The technology behind pneumatic tyre won’t go away anytime sooner with over 100 years of refinement and many improvements in the design features. These tyres are produced around the world in more than 450 factories approximately. Basic elements are rubber, carbon black and many other chemical compositions.

Wheels are assembled on a drum with heat and pressure application that creates polymerisation; linking rubber monomers. The reaction also creates an elastic chain of molecules which compresses the tyre to a point where rubber touches the road and regains its original shape. Pneumatic tyres support the wheel rim in many different ways such as tension in the cords pull the bead evenly around the wheel as well as the road contact section.

Then came the radial cords in the 1940s by Michelin that eventually superseded the cross-ply designs with reduced temperature, durability, and less rolling resistance. Each manufacturer of tyre in Dubai at this point uses their own compounds with just the perfect balance of durability and performance.

Something “New” With Pneumatic:

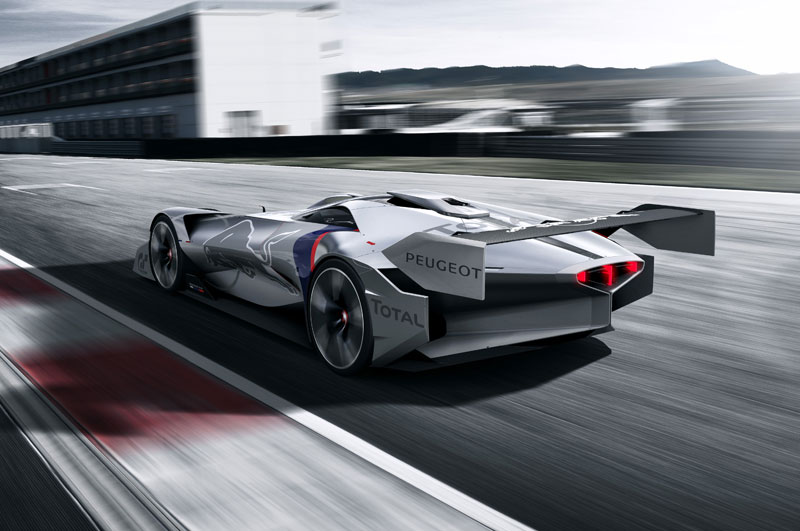

Perhaps the greatest pace in recent years is towards the precision engineering of each tyre in combination with improved rubber compounds and data-aggregation tools. Each must be accordingly to the vehicle and tyre built as the wrong fit may seriously compromise road safety and driving comfort.

“Digital tyres” for instance are being tested on the FXX-K supercar from Ferrari for the sake of data collection over the coefficient of friction, pavement grade, and footprint. The information is then shared with a traction control system and ECU of the car to optimise delivery based on grip.

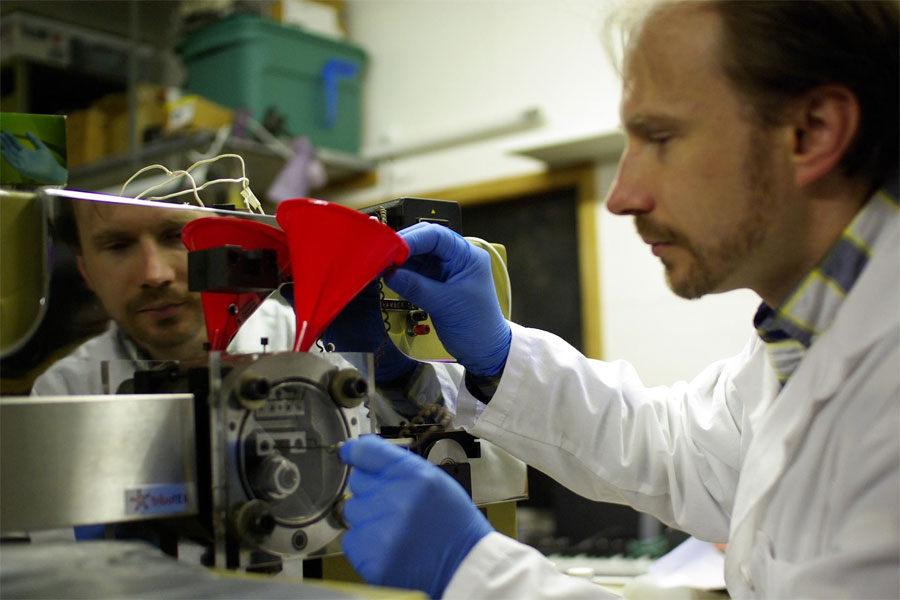

Michelin; once again came up with something entirely radical that is a self-healing or self-evolving tyres as it wears for smooth driving and lasting performance. These self-inflating tyres are also being explored in the consumer market using sensors to monitor the pressure within the wheels.

Conclusion:

With every other industry, tyre manufacturing is also evolving and getting better day by day!